What We Manufacture

- Electronics and wire harness assemblies

- MIL-STD-1553 data bus products

- Precision machined products and sheet metal fabrications

Leveraging Phoenix Defense’s Engineering Services work with the military, we recently began producing stationary infantry targets, mobile infantry targets, stationary armored targets and mobile armored targets for the U.S. Army.

Electronics and Wire Harness Assemblies

We produce an array of components for military and commercial industries.

- Wire harnesses from simple to complex uses, meeting demands such as custom marking, over-molding and over-braiding

- Radio frequency and microwave connectors

- High-speed data transmission solutions

- Electrical and hardware components for combat simulators

- Integrated avionics kits for military

- Cockpit and lighting panels

- Electronics and wire harness assemblies

MIL-STO-1553 Data Buses

- We build a wide variety of data bus components to the exacting MIL-STD-1553 standard for use in military and civil aircraft, space systems, ground combat systems and other equipment.

- All our standard and custom designs are built to provide exceptional reliability and perform in the most rigorous environments, whether in flight, on the ground or in space.

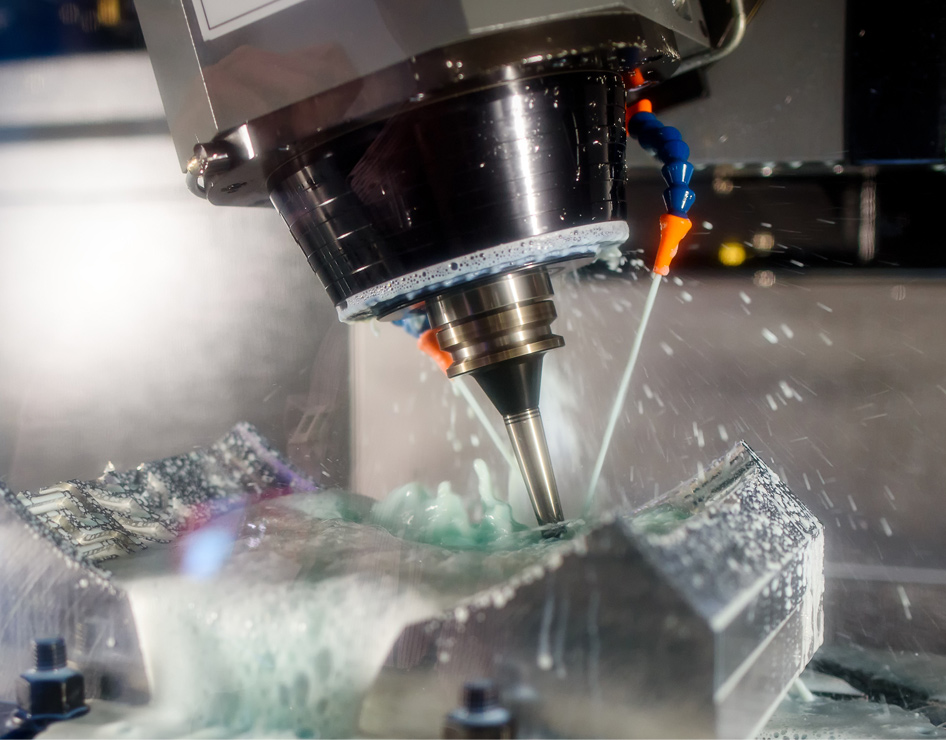

Machining and Sheet Metal Fabrication

- Our capabilities include precision sheet metal fabrication, CNC machining and turning, grinding, assembly, tooling and finishing.

- We are a proven one-stop shop for customers including Honeywell, Boeing Defense Systems, Raytheon and Gulfstream.

- ISO 9001:2015 (QMS)

- AS9100D

- AS9110

- AS9102

- AS9146/ NAS 412

- AS5553/AS6174

- ISO 10012

- IPC/WHMA-A-620

- IPC/WHMA-A-620-S

- IPC J-STD-001

- IPC J-STD-001S

- NASA-STD-8739.4

- NASA-STD-8739.1

- DOTC (ITAR)

- DCAA/TINA/CAS COMPLIANT

Certified

Quality

Where We Excel

- Three manufacturing facilities in Gilbert, Arizona, totaling 85,000 square feet of space.

- Lean manufacturing operations allow us to exceed the tightest customer standards and precision requirements.

- High-speed prototyping capabilities shorten time to production.

- Production facilities are temperature and humidity-controlled to perform state-of-the-art CNC aerospace machining, electronics and wire harness assembly.

Our Work Earns Recognition

We play a mission-critical role for both military and commercial customers with production lines serving the F35, C17, V22 Osprey, P8A, F18 and KC-135 aircraft (to name a few). Phoenix Defense is a key supplier to such military rotorcraft as the UH-60 Blackhawk, CH47 Chinook, AH64 Apache Longbow, and AH-1W.

Our quality and innovation bring kudos from customers. Honors include the Bell Helicopter Superior Rating, Northrop Grumman Platinum, Boeing Performance Excellence Award and Lockheed Martin Preferred Supplier.